Laminated glass windows are a common choice for residential buildings in the world today. Even though this may not be the only choice for glass windows, we can recommend that this is one of the best and ideal solutions for residential buildings in the modern world.

Laminated glass is known widely as laminated safety glass because it is a form of safety glazing made by joining two sheets of glass with an internal layer of an extra protective layer of vinyl between them. This middle layer holds the glass together so that even when the glass breaks, the shards of glass are held together and are not shattered everywhere. Thus, only cracks are created. This inseparable bond is created by applying heat and pressure. Due to this process, the glass is made safe and less likely to break out of the frame.

The typical laminated glass referred to as size 5.38 is made up of two layers of 2.5 mm glass and one interlayer of 0.38 mm. All colors and thicknesses can be created using glass and interlayers. The performance characteristics can also be created in order to get the required appearance and appeal. Let’s identify the differences between laminated glass and tempered glass.

Table of Contents

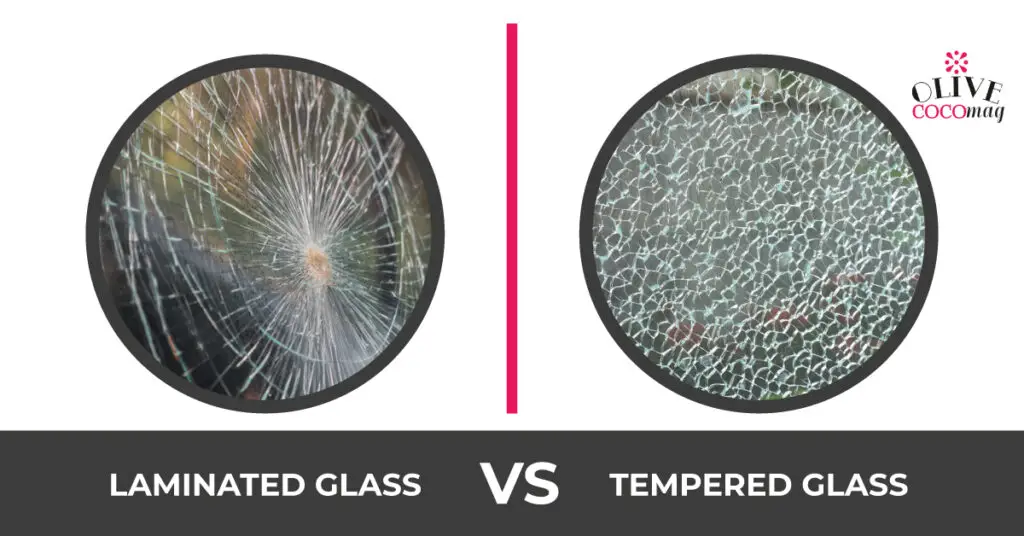

Laminated Glass VS Tempered Glass

Tempered glass is also a form of safety glass that is made in such a way to enhance the strength of the glass. This is made by toughening the glass at high temperatures and pressures along with chemical treatment procedures. In the laminated glass, a single sheet is made with multiple layers of glass, and a plastic resin is used to hold the glass together. Treatment of glass under these conditions gives them an ability to have a good balance of internal stress and high resistive forces.

Laminated glass is considered to be strong as it can withstand the impact of a rock or a bullet without shattering the glass. It is considered to be five times stronger and 100 times stiffer than the normal regular glass. However, tempered glass is considered to be of more strength than laminated glass.

Laminated glass is also more flexible than others. It flexes before shattering and also blocks harmful radiation unlike in tempered glass.

When considering the application of these two types of glasses also differ just as their strengths. Laminated glass is often used for commercial buildings and housing apartments that are interested mostly in the security from forced entry and safeguard valuables. Tempered glass is mainly used for interior safety glass applications. This means, doors of shows and tubs for home and doors of conference rooms in office buildings. Tempered glass is also used in skyscrapers where views through large windows are of commercial value and hence the outside view is not distorted.

Laminated glass is used for indoor and outdoor graphical projects such as photography and architectural glass. Since a middle polythene layer is used, visual imagery can be created on the glass well. This is used for brand marketing purposes in creating great impressions on the public.

Incorporating such digital elements is not possible in tempered glass, as they are completely made of glass only. Therefore, laminated glasses offer more design choices than tempered glasses.

As a result of the complex manufacturing process and use of many materials, laminated glass is more expensive than tempered glass. However, tempered glass is more expensive than regular glass but less expensive than laminated glass.

It is necessary to always remember that tempered glass cannot be cut that easily and might result in exploding the glass if you try to pierce the surface with improper knowledge and technology. Therefore, if you are planning to use tempered glass for windows or some other project application, make sure to size the glasses properly before it is tempered with heat and pressure treatments.

Even though laminated glasses are also hard and very difficult to be cut, there are possible methods to do it. These methods would be discussed later in this context.

These are the major differences between laminated glass and tempered glass. If you are further interested in learning about this, let’s move on to the advantages of laminated glass, in selecting for windows than the other types of glass available.

Benefits of Laminated Glass Windows

- Laminated Glass is Less Dangerous When Broken

During an impact, the normal standard that is also termed as safety glass is more likely to break easily. This means a robber or burglar could break your window glasses with one swift blow. Moreover, the glasses could even break involuntarily, and this could even lead to harmful safety risks. But on the other hand, when considering laminated glass, the chance of getting cut from edges of broken laminated glass is considerably low. This is because the inner protective layer of vinyl prevents the glass from breaking apart and exposing the sharp edges.

- Burglars Can’t Use Glass Cutters to Cut Laminated Glass.

Laminated glass cannot be cut easily from the outside easily using any tools like glass cutters. Only the outermost layer can be damaged using glass cutters. Therefore, there is less risk of thieves breaking into your house or building. Even if they try to break in with the aid of some heavy tool to shatter the glass, this would not be successful as the glass would end up cracking, but would not break. Therefore, the robbers would easily give up and leave the place. The strength of the laminated glass can be enhanced further by increasing the number of laminated layers and also the thickness of the glass.

- Less Sound Transfer Through Windows

If you are living in close apartments, you would be often concerned about the sound and noises of neighbors. The best option for you once again would be laminated glass windows. These are mostly soundproof and hence reduce or completely block off the sound that goes into your house through the glass windows. This will also be a good option if you are living in a neighborhood on the roadside with heavy traffic or noisy neighbors. Sometimes the noises can be so high and distractive that it would even cause health problems.

If you use two window panes rather than one, an air pocket would be created in between them. This is a good soundproof technique that has been used since the past. So, make the wise choice of getting soundproof laminated glasses for a better life standard.

- UV Protection

The ultraviolet rays are a form of harmful radiation that causes harm to both humans and household material. When using normal glass, these harmful radiations can penetrate through the glass and fade fabric material such as carpets, curtains, and even furniture. Closing curtains would not reduce the impact completely.

It would also block the sunlight from lighting up your living space with natural light. Therefore, the best option for this is the installation of laminated glass windows. These glasses contain a special film that is efficient in blocking off harmful UV radiation. you can safeguard your home or office by simply using these laminated glass windows and avoid unnecessary replacement of faded fabrics and also reduce health risks.

- Impact Resistant

There are naturals that might occur depending on the place you live. If you are living around the coastal area, heavy winds and thunderstorms could have huge impacts on the window glasses. Some areas even have tornados and hurricanes that occur very often. Therefore, it is always good to go for an option where the windows can handle high pressure and retain strength. Also even if the glass breaks by any chance, there should be a minimal effect on the risk of safety of the residents. Laminated glass windows offer the best safety in this concern.

They are highly stable and can withstand high impacts of pressure. These high strength laminated glasses are even used in the front and side cockpit windows of airplanes.

Every item has two sides as advantages and disadvantages. Even though we often see the advantages, good reviews, and buy the products, it is always a wise decision to review the disadvantages, negative feedback and check whether we can actually stand those drawbacks. So let’s identify the most prominent disadvantages of laminated window glasses.

Drawbacks of Laminated Glass Windows

- Poor Installation Can Lead To Many Problems

Installation is one main consideration that you need to be concerned about. The laminated glass windows should be installed properly for you to experience the best results without any hindrance. To get the full advantage, find proper professional expertise in the field.

The window glass should be installed with the exact fit and accurately sufficient airspace between the two window panes. Through this, the sound-reducing property can be maximized. If you install this incorrectly, the required function would not be done and sound dampening would be inefficient. So, you should know that this is not a direct drawback of the window glass, but an indirect disadvantage you would have to face if you do it wrong.

- Heavy Weight

The laminated glasses would be quite heavier than the standard glass. Therefore, this weight of the glass can wear off the hardware and creates unbalances by disfiguring the frame. This is not a very common occurrence but might happen over time due to low strength frames.

- Relatively High Cost

The laminated glass would cost a few dollars more per square foot than the normal standard glass. If you are planning on getting a large number of windows covered by this glass, then you would have an increased price. So, it would be ideal for you to find a way to do both the purchase and installation at a considerable price with discounts.

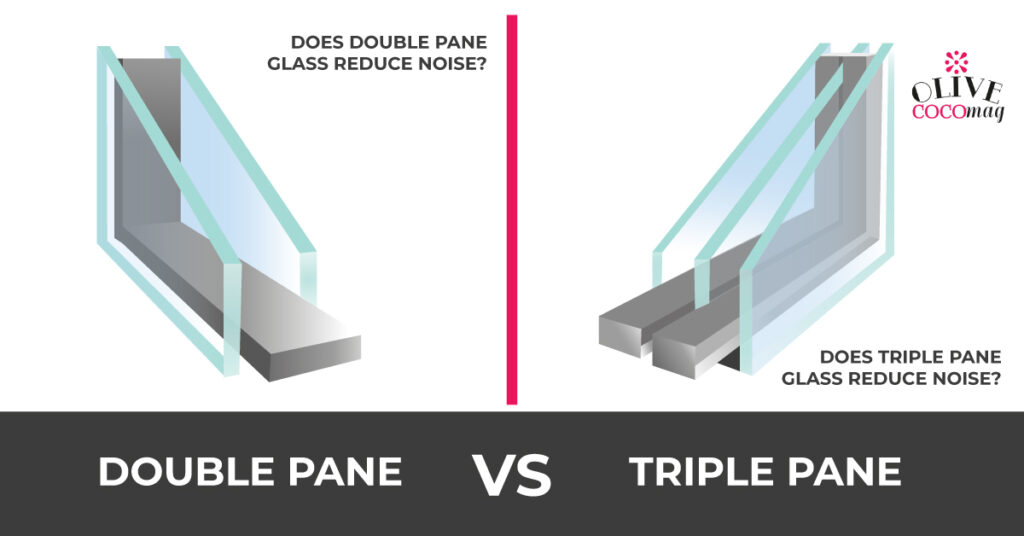

Does Triple Pane Glass Reduce Noise?

The amount of space that lies between the glass panes is directly related to the amount of sound blocked. Therefore, it can be easily concluded that sound resistance is higher in triple pane glass windows than in double pane. But in reality, it is not so. Studies have shown that using triple pane windows does not offer higher sound resistance than the usual double pane windows made of laminated glass.

Other Options to Reduce Outside Noise

If there are any cracks or gaps in between the seals, then soundproof glasses would be inefficient. You may use an airtight seal with a weather-stripping ability that would act as a barrier for keeping out unwanted noise. Additionally insulated vinyl frames that are filled with foam can also be used to block outside noise efficiently. Always choose windows with non-metal window spacer systems. This part would be made of silicone rubber and covered with a sealant which created better insulating properties than using metal counterparts.

As an added advantage, as you seal your doors and windows for noise reduction it would also workaround to save your electricity bills. This would happen as the energy efficiency of windows is high and also because the air conditioning would be optimized. So, consider this advantage when you think of installing new window glasses for your office or house.

The Cost of Laminated Glass Windows

The cost directly depends on the size and thickness of the laminated glass. The prices would also vary slightly from one manufacturer to another. You can get a rough idea about the rates and cost variations between the tempered glass and laminated glass from the example below.

- Tempered Single Hung Vinyl Window – $325

- 0.090 Laminate Single Hung Vinyl Window – $497

- 0.030 Laminate Single Hung Vinyl Window – $374

Special Features of Laminated Glass Windows

Some laminated glass windows offer a sound reduction index over 39 dB which is 1.5 times that of regular insulated glass. The U value is a factor that measures the loss of heat. The lower its value, the better the performance of the glass would be. A best laminated glass of 8.3 mm can have a U value as low as 0.4 W/ (m2.K) which is even more effective than a brick wall of 1.5 m thickness. This value would be constant irrespective of the angle the glass is mounted whether horizontal, vertical or at an angle.

Some types of improved laminated glass windows have the property of staying free of condensation even when the temperature difference of the two sides rises more than 70 degrees Celsius. It lowers the dew point simultaneously. This is ideal for buildings and observation windows in extremely hot or cold weather. It is also important for freezers, high-end refrigerators, and cold rooms related to ice cream manufacturing and similar industries.

Thin and lightweight structures are another type of new feature added to the latest models of laminated glass windows. A piece of 8.3 mm thick glass would weigh only 20 kg/ m2.

Let’s find more details about the laminated glasses, and learn what they really are.

How Laminated Glass is Made

As described in the context above, the normal laminated glasses are made with a plastic interlayer between two layers of tempered glass. The inner layer could be made of Polyvinyl Butyral, Thermoplastic Polyurethane (TPU), or EthyleneVinyl Acetate (EVA). After the three layers are placed together, it is passed through a long series of rollers and bagging systems.

This is done to remove any possible air pockets that could have been trapped inside. Then this is heated for the initial melt. These assemblies are heated under high pressure in an oven referred to as an autoclave. The final product is obtained from this. When thermostat EVA is used, then the laminate would be fully cross-linked. PVB is mainly used for creating the top part of windshields.

When the laminating is done properly with thermoset EVA the glass can be kept frameless and water or moisture would penetrate in between the layers. Very slight discoloration would occur and delaminate would not occur due to the good binding and cross-linking.

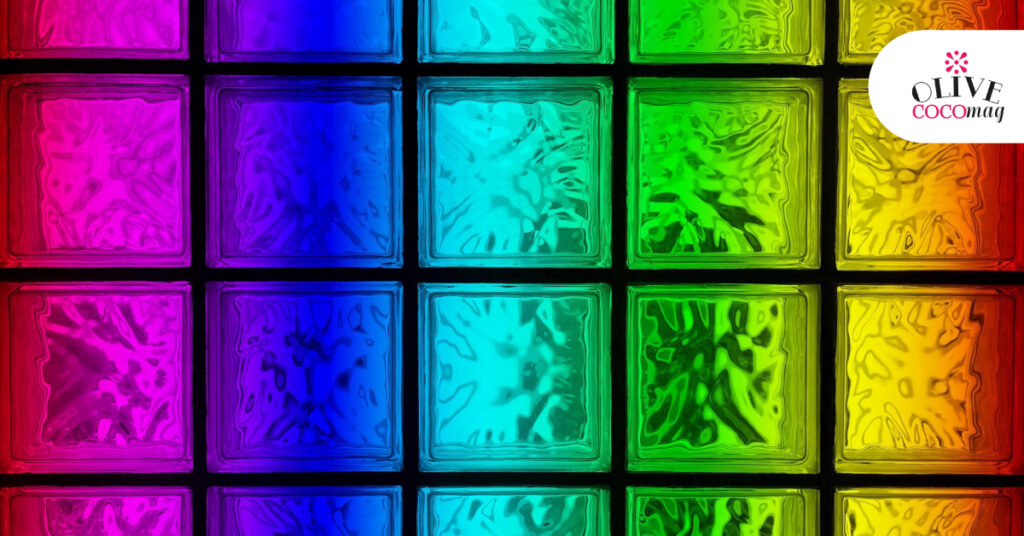

Colored and Printed Glass

Colored glasses are obtained by using colored PET films with thermoset EVA during the process of laminating. The technology has advanced for aesthetic purposes, that printing can be done directly on the glass or printed on the polythene layer before laminating. This is very popular in the interior design and signage industries. Colored interlayers are added to create a permanent transparent color that is used in the glass panels. A switchable layer can also be added in between the glass layers to get a clear look when a small current is passed through it, while it would be opaque when the current is switched off. This consists of:

- Top layer: Glass

- Interlayer 1: Transparent thermoplastic materials (TPU or PVB, EVA) or transparent thermoset material (EVA)

- Interlayer 2: LED (light emitting diodes) on transparent conductive Polymer

- Interlayer 3: Same as interlayer 1

- Bottom layer: Glass as in top layer

Cutting Laminated Glass

Cutting laminated glass is extremely difficult to the added strength of the plastic interlayers. So, there is a method followed to cut these glasses, but is unsafe and could be hazardous. The method is by cutting the two glass sides separately and igniting the middle layer to melt by pouring a flammable liquid into the crack. Then the interlayers would be separated into pieces and the glass would be cut accordingly. However, some other safety methods have been recommended such as:

- Special purpose laminated cutting tables

- Vertically-inclined saw frames

- A blowlamp or hot air blower

- High pressure abrasive water jet

Repairing Options

As stated by the United States National Windshield Repair Association, laminated glass repair for minor impact damages can be done using a special procedure. This process is done by drilling into the fractures glass until the lamination layer is reached. Then a special resin of clear adhesive is injected under high pressure. Next, it is cured well using ultraviolet light. On proper completion of this process, the strength and the clarity of the glass are mostly restored and suitable for safety related purposes. This process is widely used for laminated glasses that do not have problems related to vision through it.

Waste Disposal of Laminated Glass

The use of laminated glasses for landfills is prohibited. As an alternative, recycling these glasses using a separating device with a rolling mill is done. Once the glass is fragmented, the larger cullet is removed mechanically from the inner film. Then heat is applied to melt the laminating plastic and thus, both the glass and inner film can be recycled. The non-cross-linked plastics are easy to be recycled in this way.

Applications of Laminated Glass

The following are some of the main uses and applications of laminated glass, apart from using them merely as glass windows.

- Laminated glass windows are used in buildings with a high risk from hurricanes or other natural disasters. During any such impact such as earthquakes, the glasses would take time to shatter and the residents can escape quickly before any major harm occurs.

- These are also used for windows in companies and houses at higher risk of break-ins.

- Laminated glass windows are used for display cabinets of valuables, such as in showrooms and jewelry stores where it is most vulnerable to robberies.

- Balcony railings are also made with laminated glass to ensure protection from impact and also to get a more pleasing aesthetic appeal. This would also help to get a better view without any obstruction even for kids.

- You might know the concept of “infinity swimming pools” where water flows over the edge and creates an illusion of a boundless pool. These pools too are constructed using laminated glass in order to resist the high pressure of water without any frame.

- Aquariums and animal enclosures in most zoos are built with laminated glass that is so large and is almost glass windows. These are used for high strength and also to block harmful radiation that might cause damage to the animals dwelling inside.

- Glass floors are typically made up of laminated glass since ordinary glass cannot stand the foot traffic and would break easily. A good example would be the glass bridges that are currently one of the most adventurous sites that attract many tourists and visitors.

- Glass stairs are also a form of very appealing aesthetic creation where these laminated glasses are used.

- Skylights and glass roofs are also economically valuable uses of laminated glass that is mostly used for commercial purposes.